Welcome to Structural Analysis Consultants!

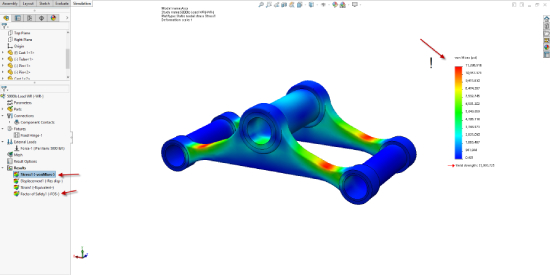

Using the latest in finite element analysis software, we provide structural analysis services to engineering and design professionals who require accurate simulations for their product designs.

Our goal is to help you with the following:

- optimize your product designs,

- reduce your product development time,

- minimize your product development costs,

- improve the safety and performance of your products,

- minimize your product design risks, and

- help you better understand the behaviour of your products under real-world conditions.

Our design and analysis experts specialize in assessing the loading of welded structures, and we can provide design failure and fatigue analyses to help you ensure that your products will function safely and as intended.